-78512896-e8f7-4b45-82bb-83ff8356b0db.png)

Abstract

Our innovative method for ethanol production from molasses offers a 3% increase in yield without the need for additional equipment, pH adjustments, or changes to existing workflows. This cost-effective solution not only enhances production efficiency but also captures CO₂ emissions for sustainable applications in food preservation. Tested and successfully scaled across six companies, our method enables the production of food-grade ethanol while maintaining low operational costs. We are ready to transfer this proven know-how to companies looking to maximize yields and sustainability in ethanol production.

Description

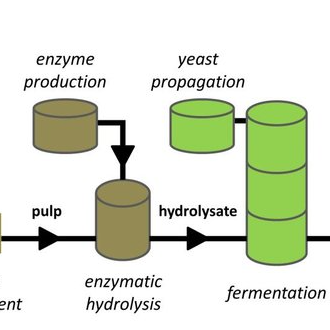

Ethanol is the major product obtained from the molasses by means of fermentations using microorganisms. During this process, there is a release of carbon dioxide that will be utilized in the food preservation industries.

The most critical factors that determine the economic feasibility of ethanol production from agricultural product feedstocks are ethanol yields per unit of feedstock and the cost of the feedstock. It is economically feasible to make ethanol from molasses as the cost of that feedstock is really low.

Commonly, molasses enter the fermentation part without any treatment in the companies that produce ethanol from molasses (sugar beet and sugarcane). We have developed a new method for producing ethanol more efficiently. In this method, molasses was treated and yield of ethanol increased to 3% with lowest cost.

No special equipment is needed

No pH adjustment is needed

No change in flow of molasses

Producing food grade materials

Scale-up in 6 companies

We are ready to transfer this know-how to the relevant companies who want to increase their production yields.

Pricing Options

- One time license:

Targeted Customers

- Ethanol Production Companies

- Agricultural Product Feedstock Companies

Value proposition

- Boost Ethanol Yields by 3%

- Cost-Effective

- No Equipment Needed

- Seamless Integration into Existing Processes

- Sustainable CO₂ Utilization

- Proven Success in Six Companies

- Food-Grade Ethanol Production Simplified